PDF(14092 KB)

PDF(14092 KB)

PDF(14092 KB)

PDF(14092 KB)

PDF(14092 KB)

PDF(14092 KB)

316L不锈钢蜂窝夹芯结构的抗爆性能研究与优化

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}

({{custom_author.role_cn}}), {{javascript:window.custom_author_cn_index++;}}Study and Optimization on Blast Resistance of 316L Stainless Steel Honeycomb Sandwich Structures

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}In order to investigate the blast resistance of a 316L stainless steel honeycomb sandwich structure, a honeycomb sandwich structure was designed and fabricated using 316L stainless steel powder by selective laser melting (SLM). Concurrently, solid panels of equivalent surface density were produced by this method and constituted the control group. The mechanical behavior of the structure under near-field static explosion load is obtained through static explosion experiments and LS-DYNA simulation experiments, and the propagation mode of the stress wave within it is investigated in order to elucidate the underlying anti-explosion principle. Moreover, optistruct is utilized to optimize the topology and structure of the structure, with the objective of enhancing its blast resistance. The findings indicate that the backplate deflection of the porous sandwich structure is diminished by 13.2% in comparison to that of the plate with isoplanar density, thereby enhancing blast resistance. The established numerical model of fluid-solid coupling is capable of describing the three phases of the static explosion experiment, namely the shock wave propagation phase, the fluid-solid coupling phase, and the inertia phase. The explosion experiment yielded definitive results at the center of the target plate, thereby demonstrating that the "川" crack is caused by residual core layer extrusion. Moreover, the core layer deformation failure mechanism for the honeycomb panel was observed to manifest as in-plane stretching and tearing. The optistruct optimization results demonstrate the formation of a triangular skeleton and circular holes, alternating with corrugated plates. The structure, optimized for a corrugated core target plate, displays enhanced resilience in comparison to the optimization of a traditional honeycomb sandwich panel. The explosion load backboard deflection exhibited a 25.4% reduction, the peak pressure behind the plate demonstrated a 17.6% reduction, and the blast resistance was significantly enhanced. In comparison to honeycomb panels, the circular hole structure has been demonstrated to reduce the backplane deflection by 38.1%, while the triangular hole structure has been shown to reduce the peak pressure behind the plate by 22.4%.

316L 不锈钢 / 金属多孔夹芯结构 / 抗爆性能 / 抗爆机理 / 结构优化 / 选区激光熔融 {{custom_keyword}} /

316L stainless steel / metal porous sandwich structure / blast resistance properties / blast resistance mechanism / structure optimization / selective laser melting {{custom_keyword}} /

表1 316L不锈钢粉末材料元素配比Table 1 316L stainless steel powder composition |

| Element | wt/% | Element | wt/% |

|---|---|---|---|

| Fe | leftover | Si | 0.54 |

| Cr | 16~18 | C | ≤0.03 |

| Ni | 10~14 | S | ≤0.03 |

| Mo | 23 | P | ≤0.04 |

| Mn | ≤2 |

表2 工况组参数设置Table 2 Settings of testing conditions |

| Number | Structure | SoD/mm | TNT mass/g |

|---|---|---|---|

| 1 | Honeycomb | 50 | 55 |

| 2 | Plate with isoplanar density | 50 | 55 |

表4 TNT主要材料参数Table 4 Main material properties of TNT |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| ρ/(g/cm3) | 1.63 | b/GPa | 3.75 |

| VD/(m/s) | 6 930 | R1 | 4.15 |

| PCJ/GPa | 21 | R2 | 0.9 |

| a/GPa | 373.8 | | 0.35 |

图11 平均压力峰值衰减单元选取区域Fig.11 The selected area for calculating the average peak pressure |

| [1] |

张自强, 赵宝荣, 张锐生. 装甲防护技术基础[M]. 北京: 兵器工业出版社, 2000.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [2] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [3] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [4] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [5] |

王迪, 李九霄, 董安平, 等. 熔模铸造型壳用材料研究进展[J]. 精密成形工程, 2023, 15(4): 205-216.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [6] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [7] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [8] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [9] |

沈鹤飞, 赵民, 徐智宝, 等. 表面处理工艺对单组分聚氨酯密封胶与不锈钢粘接的影响[J]. 轨道交通材料, 2023, 2(3): 22-26.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [10] |

张保林, 宋丽平, 燕样样, 等. 304/Q345R不锈钢复合板焊接工艺与焊接缺陷分析[J]. 南方农机, 2019, 50(23): 35-36.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [11] |

何文信. 基于点焊及粘接结构的不锈钢车体强度研究[D]. 成都: 西南交通大学, 2018.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [12] |

张长仔. 空中近场爆炸载荷下泡沫铝波纹杂交夹层板动态响应研究[D]. 武汉: 华中科技大学, 2017.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [13] |

周天宇. 近场/接触爆炸载荷下 PVC 泡沫夹芯结构动态响应和失效机理研究[D]. 武汉: 华中科技大学, 2019.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [14] |

李小帅, 黄静泊, 谢晶, 等. 连接方式对蜂窝夹芯结构抗爆性能的影响规律研究[J]. 包装工程, 2024, 45(19):29-40

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [15] |

韦雄棉, 王迪, 杨永强, 等. 激光选区熔化钛合金多孔结构拉伸性能研究[J]. 中国激光, 2021, 48 (18):149-162.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [16] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [17] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [18] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [19] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [20] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [21] |

周建. 选择性激光熔化316L不锈钢粉末数值模拟及实验研究[D]. 镇江: 江苏大学, 2019.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [22] |

刘涛, 尹志强, 雷经发, 等. 选区激光熔化316L不锈钢高应变率压缩下的塑性变形行为[J]. 材料研究学报, 2023, 37(5):391-400.

对选区激光熔化316L不锈钢(SLM-316L)的高应变率(1000、2000、3000 s<sup>-1</sup>)压缩力学性能进行测试,用扫描电镜和背散射衍射(EBSD)等手段表征冲击加载前后试样的微观结构,并分析晶体结构的差异以及位错滑移、孪生行为等微观变形机制。结果表明:SLM-316L不锈钢在高应变率载荷作用下有显著的应变率强化效应,其微观组织由截面呈不规则多边形的柱状胞晶密排结构组成,高应变率加载使晶体取向的择优性降低、小角度晶界和孪晶界数量增加,且孪晶界在小角度晶界的交叉缠绕区分布密集,试样的塑性变形过程伴随着位错滑移及孪生行为。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [23] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [24] |

徐自强, 王丽娟, 朱洁, 等. PBM算法在近场爆炸数值模拟中的运用研究[J]. 爆破, 2022, 39(1): 29-35.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [25] |

刘树森, 何小伟, 王文成, 等. 光滑粒子流体动力学流体仿真技术综述[J]. 软件学报, 2024, 35(1): 481-512.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [26] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [27] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [28] |

汪春辉, 王嘉安, 王超, 等. 基于S-ALE方法的圆柱体垂直出水破冰研究[J]. 力学学报, 2021, 53(11): 3110-3123.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [29] |

薛浩, 王涛, 黄广炎, 等. 增材制造316L不锈钢球形破片的弹道性能[J]. 兵工学报, 2024, 45(2):395-406.

为探索增材制造316L不锈钢球形破片的弹道性能,采用选择性激光熔化(Selective Laser Melting,SLM)技术制造316L不锈钢材料毛坯,通过机加工、抛光等操作得到了直径12mm的增材制造316L不锈钢球形破片。开展打印态316L不锈钢材料的显微计算机断层扫描(Computed Tomography, CT)和静动态力学试验研究,获得了打印态316L不锈钢在材料沉积方向的Johnson-Cook(JC)模型参数,进行了增材制造和传统冷轧工艺制造的316L不锈钢球形破片侵彻6mm厚Q235钢靶的弹道试验。研究结果表明:增材制造球形破片的弹道极限速度比传统冷轧制造破片低2.5%左右,弹道性能有小幅提升,暗示了增材制造工艺用于制造战斗部预制破片的潜力;开展的数值仿真研究获得了与试验结果一致的剪切冲塞穿靶机理,仿真与试验穿靶速度数据比较吻合,弹道极限速度误差仅为1.4%左右,仿真结果也表明JC模型用于描述增材制造316L不锈钢材料穿靶行为的可行性。

The ballistic performance of additively manufactured 316L stainless steel (AM SS316L) spherical fragments is explored in this study. The SS316L blanks are printed by using selective laser melting (SLM) technology. AM SS316L spherical fragments with 12mm diameter are obtained by the machining and polishing processes. The micro-computed tomography (CT), static and dynamic mechanical tests of the as-built SS316L are conducted, and Johnson-Cook (JC) material parameters in the material deposition direction are obtained for SS316L materials. Hereafter, the ballistic test of AM and traditional cold-rolled SS316L fragments penetrating a 6.0mm-thick Q235 steel target is carried out. The test results show that the ballistic limit velocity of AM SS316L spherical fragments is lower than 2.5% than that of the cold-rolled fragments and its ballistic performance is slightly improved, indicating the potential of the AM technology in fabricating the pre-formed fragments. Finally, the numerically simulated results show a shear plugging mechanism consistent with experimental results. The simulated and test velocity perforation data have a good agreement, and the ballistic limit velocity error is only about 1.4%. At the same time, the simulated results also show that the JC model can be used to describe the perforation behaviors of AM SS316L materials. {{custom_citation.content}}

{{custom_citation.annotation}}

|

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

PDF(14092 KB)

PDF(14092 KB)

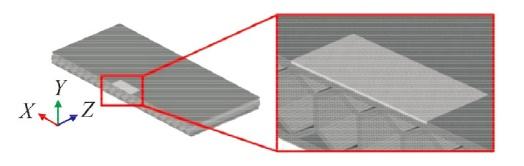

图1 蜂窝夹芯结构尺寸示意图(单位:mm)

图1 蜂窝夹芯结构尺寸示意图(单位:mm) 表1 316L不锈钢粉末材料元素配比

表1 316L不锈钢粉末材料元素配比 图2 爆炸实验平台现场图

图2 爆炸实验平台现场图 表2 工况组参数设置

表2 工况组参数设置 图3 蜂窝板和等面密度实心板变形失效结果图

图3 蜂窝板和等面密度实心板变形失效结果图 图4 背板挠度曲线对比图

图4 背板挠度曲线对比图 图5 整体变形截面对比图

图5 整体变形截面对比图 图6 蜂窝板芯层压溃变形横向分布图

图6 蜂窝板芯层压溃变形横向分布图 图7 有限元模型示意图

图7 有限元模型示意图 表3 316L不锈钢Johnson-Cook模型材料参数[29]

表3 316L不锈钢Johnson-Cook模型材料参数[29] 表4 TNT主要材料参数

表4 TNT主要材料参数 图8 仿真与实验裂纹形貌及芯层压溃对比图

图8 仿真与实验裂纹形貌及芯层压溃对比图 图9 载荷传递各阶段示意图

图9 载荷传递各阶段示意图 图10 靶板响应示意图

图10 靶板响应示意图 图11 平均压力峰值衰减单元选取区域

图11 平均压力峰值衰减单元选取区域 图12 靶前靶后压力变化时程曲线

图12 靶前靶后压力变化时程曲线 图13 单元选取示意图

图13 单元选取示意图 图14 各单元X方向应变时程曲线

图14 各单元X方向应变时程曲线 图15 各单元XOY平面内剪应变时程曲线

图15 各单元XOY平面内剪应变时程曲线 图16 蜂窝板面板拉伸撕裂破坏模式有限元示意图

图16 蜂窝板面板拉伸撕裂破坏模式有限元示意图 图17 拓扑优化流程图

图17 拓扑优化流程图 图18 优化前后结构对比图

图18 优化前后结构对比图 图19 优化前后背板中心点位移时程曲线

图19 优化前后背板中心点位移时程曲线 图20 优化前后背板中心平均压力时程曲线

图20 优化前后背板中心平均压力时程曲线 图21 圆孔板与三角板示意图

图21 圆孔板与三角板示意图 图22 3种靶板应力云图

图22 3种靶板应力云图 图23 3种靶板背板中心点位移时程曲线

图23 3种靶板背板中心点位移时程曲线 图24 3种靶板应变能累积时程曲线

图24 3种靶板应变能累积时程曲线 图25 3种靶板背板中心点平均压力时程曲线

图25 3种靶板背板中心点平均压力时程曲线 图26 3种靶板截面压溃历程

图26 3种靶板截面压溃历程/

| 〈 |

|

〉 |