PDF(2866 KB)

PDF(2866 KB)

Study on Isostatic Pressing Method for Metal and Non-metal Mixed Powders Oriented to Energetic Materials

ZHANG Ke, HAN Mengwei, GE Zaizheng, WANG Guangyu, WU Feng, LIU Aijun, ZHENG Changjun

JPRMG ›› 2025, Vol. 45 ›› Issue (1) : 115-121.

PDF(2866 KB)

PDF(2866 KB)

PDF(2866 KB)

PDF(2866 KB)

Study on Isostatic Pressing Method for Metal and Non-metal Mixed Powders Oriented to Energetic Materials

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}

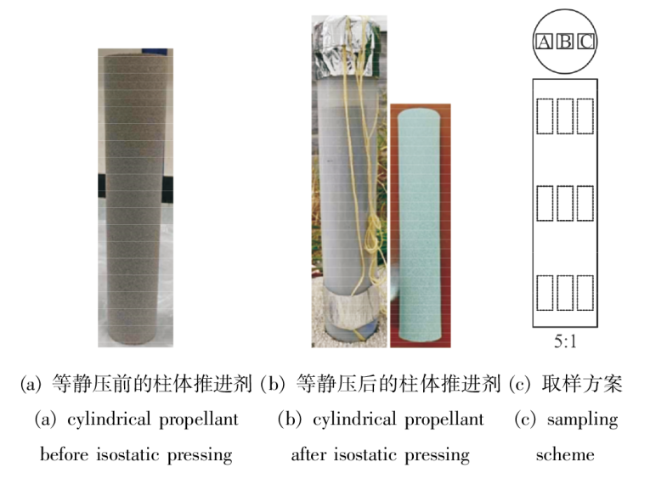

({{custom_author.role_en}}), {{javascript:window.custom_author_en_index++;}}The quality of explosive charge is a key factor affecting the performance of artillery weapons, and the explosive charge is often a mixture of powders. To improve the quality of cylinders made by a mixture of metal and non-metal powders, the mechanical behavior of the cylinders was described using continuum plasticity theory, the Shima-Oyane model and the Ogden model were employed as the material constitutive models for the cylinders and the rubber sleeve, respectively. And a simulation model for the isostatic pressing of cylinders was developed utilizing the nonlinear finite element software MSC.Marc. Based on the simulation model, the forming mechanism of cylinders was explored, and a comparative study was conducted on the influence of isostatic pressing process parameters on the forming quality of the cylinders. The results indicated that the simulation model could effectively reflect the forming characteristics of the cylinders. The maximum pressure and it’s holding time of isostatic pressing were the key factors that influenced the quality of the cylinders. When the pressure was set at 240 MPa and the holding time exceeded 400 s, the overall relative density of the cylinders reached above 97%, with the density distribution difference was below 0.5%. The results of the isostatic pressing experiment verified the accuracy of the simulation analysis results. The cylinders with approximate length-to-diameter ratios of 5∶1 achieved a higher process standard and satisfied the process requirements.

isostatic pressing of explosive charge / finite element analysis / mixed powders / charge density {{custom_keyword}} /

Table 1 Revised parameters of Shima-Oyane model表1 修正后的Shima-Oyane模型参数 |

| | | | | | | | |

|---|---|---|---|---|---|---|---|

| 0 | 1 | 1 | 9.5 | 18 | -18 | 1 | -0.3 |

Table 2 Parameters of the Ogden model表2 Ogden模型参数 |

| Parameter | Value |

|---|---|

| | 0.242 751 70 |

| | 5.982 329 45 |

| | -7.169 788 95 |

| | 0.456 011 27 |

| | 0.004 567 31 |

| | 0.000 251 41 |

Fig.8 Results of isostatic pressure experiment and sampling scheme for inspection图8 等静压实验结果及检测取样方案 |

Table 3 Co of experimental and simulation results表3 实验结果与仿真结果对比 |

| Result | Diameter/mm | Height/mm | Average relative density of TMD/% |

|---|---|---|---|

| Simulation | 63.0 | 322.9 | 97.217 |

| Experiment | 62.43 | 331.6 | 97.41 |

| Relative error | 0.91 | 2.63 | 0.20 |

| [1] |

韦丁, 王琼林, 严文荣, 等. 降低身管烧蚀性研究进展[J]. 火炸药学报, 2020, 43(1): 351-361.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [2] |

张涛, 肖洋, 郭晓红, 等. 不同装药工艺对装药安定性的影响[J]. 弹箭与制导学报, 2011, 31(2): 86-88.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [3] |

孙建. 等静压炸药装药技术发展与应用[J]. 含能材料, 2012, 20(5): 638-642.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [4] |

何山, 蔡高参, 潘昱枫. 钛合金粉末叶轮盘热等静压成形性能[J]. 粉末冶金材料科学与工程, 2024, 29(3): 172-180.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [5] |

彭旭, 朱德贵, 李杨绪, 等. ALN-BN复相陶瓷的热等静压制备与性能研究[J]. 无机材料学报, 2016, 31(5): 535-541.

以氮化铝(AlN)和氮化硼(BN)为原料, 无烧结助剂、热等静压烧结制备了AlN-BN复相陶瓷, 研究了热等静压温度和压强对两种不同原料配比(摩尔比)烧结试样的微观结构和性能的影响。结果表明: 增加BN的添加量对复相陶瓷的烧结致密化影响较小, 但逐渐降低硬度和热导率、增大体积电阻率。相同原料配比下, 复相陶瓷的密度越高, 其热导率、体积电阻率、硬度越高。热导率和体积电阻率的实测值与两相复合模型方程较为符合。当n<sub>AlN</sub>:n<sub>BN</sub>=75:25时, 在温度为1600℃、压强为90 MPa、保温3 h的热等静压工艺下可以制备出相对密度达98.03%、热导率为77.29 W/(m·K)、体积电阻率为1.35×10<sup>15 </sup>Ω·cm的复相陶瓷。

AlN-BN composites were fabricated by hot isostatic pressing (HIP) without sintering aid, using aluminum nitride (AlN) and boron nitride (BN) powders as raw materials. The effects of HIP temperature and pressure on microstructure and properties of composites with two different raw material ratios (molar ratio) were investigated. The results show that increasing amount of BN has little impact on densification, but decreases the hardness and thermal conductivity while increases the volume resistivity. The higher the density of the composite is, the higher thermal conductivity, volume resistivity and hardness are. The thermal conductivity and volume resistivity values conform the formula: {{custom_citation.content}}

{{custom_citation.annotation}}

|

| [6] |

肖忠良, 丁亚军, 李纯志. 发射药与装药技术发展展望[J]. 含能材料, 2024, 32(8): 864-870.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [7] |

尤萌萌, 潘诗琰, 申小平, 等. 粉末压制过程数值模拟的研究现状及展望[J]. 粉末冶金工业, 2017, 27(4): 49-58.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [8] |

曹兴, 赵捍东, 曹红松, 等. 炸药粉末压制工艺参数对药柱质量的影响[J]. 火炸药学报, 2021, 44(1): 72-77.

为了得到高反应活性的铝热剂体系,以四氢铝锂和三氯化铝为原料合成了氢化铝(AlH<sub>3</sub>),利用其高活性进一步与纳米氧化铁(Fe<sub>2</sub>O<sub>3</sub>)制备了多个化学计量比(φ)的氢化铝/氧化铁(AlH<sub>3</sub>/Fe<sub>2</sub>O<sub>3</sub>)复合材料; 采用X射线衍射(XRD)、扫描电子显微镜(SEM)、能谱仪(EDS)等对复合材料的结构形貌进行了表征; 利用热重分析法(TG)和差示扫描量热法(DSC)研究了样品的热性能。结果表明,AlH<sub>3</sub>样品中少量为α-AlH<sub>3</sub>,大部分为无定形AlH<sub>3</sub>; AlH<sub>3</sub>/Fe<sub>2</sub>O<sub>3</sub>复合材料中AlH<sub>3</sub>与Fe<sub>2</sub>O<sub>3</sub>复合较好,Fe<sub>2</sub>O<sub>3</sub>在AlH<sub>3</sub>颗粒表面分散较为均匀,具有良好的热性能。φ取0.6时,AlH<sub>3</sub>过量,放热量为810.2J/g; φ取2.0时,Fe<sub>2</sub>O<sub>3</sub>过量,放热量为626.5J/g; 这两个化学计量比下的反应程度不高,放热量较低; φ取1.0时,反应放热量最大,为2181.6J/g,表明在此计量比条件下反应较为完全。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [9] |

马宏昌, 何力军, 李志年, 等. 多孔铍的屈服准则[J]. 稀有金属, 2020, 44(9): 949-956.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [10] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [11] |

陈朗, 鲁建英, 张明, 等. 药柱等静压实验和数值模拟计算[J]. 高压物理学报, 2008, 22(2): 113-117.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [12] |

贾宪振, 王晓峰, 陈松, 等. 炸药等静压工艺安全性的数值模拟研究[J]. 兵工自动化, 2014, 33(7): 65-67.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [13] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [14] |

周志平, 崔庆忠, 王自豪, 等. 黑火药致密化成型及数值模拟分析[J]. 兵工自动化, 2021, 40(2): 88-92.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [15] |

任学平, 康永林. 粉末塑性加工原理及其应用[M]. 北京: 冶金工业出版社, 1998.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [16] |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [17] |

董海山, 周芬芬. 高能炸药及相关物化性能[M]. 北京: 科学出版社, 1989.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [18] |

钱胜, 陆益民, 杨咸启, 等. 橡胶材料超弹性本构模型选取及参数确定概述[J]. 橡胶科技, 2018, 16(5): 5-10.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [19] |

王德广, 吴玉程, 焦明华, 等. 粉末成形过程中摩擦行为研究进展[J]. 机械工程学报, 2009, 45(5): 12-19.

粉末成形过程中的摩擦行为是一个十分复杂的问题,受粉末和模具材料性能、粉末形状大小、模具表面状况、粉末与模具间相对运动速度、润滑剂特性、粉末和模具温度等许多因素的影响。摩擦造成了制品密度低、分布不均匀、模具磨损,影响了制品的性能、尺寸精度及其应用范围。特别是复杂形状、厚度尺寸较大的粉末冶金制品,摩擦的存在极易造成制品的失效。摩擦行为的复杂性使得对其进行准确的测定和表达比较困难,加之这方面的研究不多,造成了进一步研究的困难。综述近几年国外对粉末成形过程摩擦现象的研究进展,着重介绍目前常用的两种摩擦测试和描述方法,即闭模式和剪切板式摩擦测定方法,为进一步研究粉末成形中的摩擦行为、提高制品性能提供参考。

The friction behavior is a very complicated problem during powder forming. There are many factors affecting the friction behavior, which include properties of powder and dies, morphology and size of powder, surface condition of dies, relative velocity between dies and powder, properties of lubricant, temperature of die and powder, and so on. The existence of friction causes low density, uneven density distribution, and die wear, thereby affecting the performance, dimension precision and application range of powder metallurgy products. Friction will easily cause the failure of PM parts, especially those with complex shape and large thickness and dimension. The complication of friction behavior makes it difficult to be accurately measured and expressed, and the researches on it are not many, so it is difficult to make further research. Foreign research progresses of friction behavior in powder forming process are summarized, and two common methods of measurement and expression of friction are introduced, namely instrumented dies method and shear plate method. This will offer reference for further research of friction behavior in powder forming and for improving the performance of PM parts.

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| [20] |

王利侠, 戴致鑫, 周涛, 等. 压装工艺对CL-20基炸药性能及聚能破甲威力的影响[J]. 火炸药学报, 2016, 39(4): 56-60.

本文采用高温加速老化的方法,通过测定RDX/AP/HTPB复合推进剂单轴拉伸力学性能、硬度、交联密度和线性燃速等参数随老化时间的变化,利用扫描电镜等实验手段,研究了RDX/AP/HTPB复合推进剂的老化。此外,还测得了这类推进剂的热失重曲线。结果表明,以RDX部分取代AP后,提高了推进剂的热稳定性。

{{custom_citation.content}}

{{custom_citation.annotation}}

|

| {{custom_ref.label}} |

{{custom_citation.content}}

{{custom_citation.annotation}}

|

PDF(2866 KB)

PDF(2866 KB)

Fig.1 Finite element mesh model of cylinder and rubber sleeve

Fig.1 Finite element mesh model of cylinder and rubber sleeve Table 1 Revised parameters of Shima-Oyane model

Table 1 Revised parameters of Shima-Oyane model Table 2 Parameters of the Ogden model

Table 2 Parameters of the Ogden model Fig.2 Displacement condition of the cylinder

Fig.2 Displacement condition of the cylinder Fig.3 Relative density distribution results of the cylinder

Fig.3 Relative density distribution results of the cylinder Fig.4 Relative density variation at different radial positions of the cylinder

Fig.4 Relative density variation at different radial positions of the cylinder Fig.5 Stress distribution in the cylinder

Fig.5 Stress distribution in the cylinder Fig.6 Density variation at the center of the cylinder

Fig.6 Density variation at the center of the cylinder Fig.7 Variation of density distribution difference in the cylinder as a function of pressing time

Fig.7 Variation of density distribution difference in the cylinder as a function of pressing time Fig.8 Results of isostatic pressure experiment and sampling scheme for inspection

Fig.8 Results of isostatic pressure experiment and sampling scheme for inspection Table 3 Co of experimental and simulation results

Table 3 Co of experimental and simulation results/

| 〈 |

|

〉 |